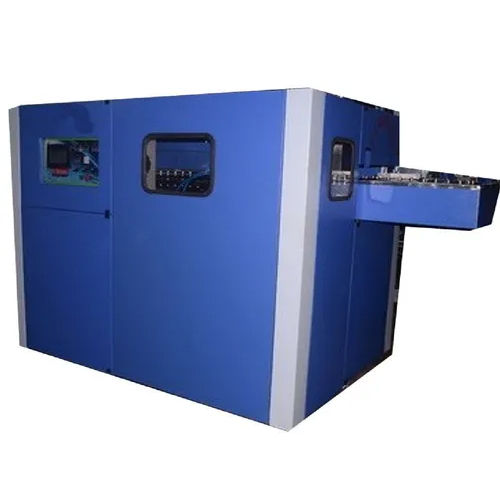

Pet Blowing Machine

Price 450000.0 INR/ Piece

Pet Blowing Machine Specification

- Control System

- Manual

- Frequency

- 50-60 Hertz (HZ)

- Voltage

- 110-215 Volt (v)

- Machine Type

- 4 Cavity Semi Automatic

- Color

- all color

Pet Blowing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Main Domestic Market

- All India

- Certifications

- msme

About Pet Blowing Machine

A PET blowing machine isspecialized equipment that transforms PET (polyethylene terephthalate) preforms into finished bottles and containers using air pressure.These machines are crucial for producing lightweight, durable, and versatile packaging for various industriesAdvanced Semi Automatic Blowing Technology

This 4 cavity semi automatic PET blowing machine combines efficiency with versatility, accommodating multiple production needs seamlessly. Its design facilitates ease of use for industrial operations, enabling fast and reliable PET bottle development. Whether for water, beverages, or other liquid packaging, its robust build and modern features help optimize your workflow.

Reliable Power and Construction

Operating on a 440 V electric supply, this machine is engineered for consistent, high-volume production. Constructed using durable components and built in a range of colors, it supports various industrial environments. The new condition guarantee and 1-year warranty ensure long-term usage with peace of mind.

FAQs of Pet Blowing Machine:

Q: How does the 4 Cavity Semi Automatic PET Blowing Machine operate?

A: The machine utilizes a semi-automatic process where preforms are placed into the machine manually. Using electric power (440 V), it then heats and blows the preforms into PET bottles using its four-cavity mold, enabling efficient bottle production.Q: What are the industrial applications for this PET blowing machine?

A: This machine is suitable for manufacturing PET bottles commonly used in packaging beverages, water, edible oils, pharmaceuticals, and more. Its design caters to diverse industrial requirements, promoting versatility in use.Q: When should I perform maintenance on the machine?

A: Regular preventive maintenance is recommended based on usage frequency. Basic checks, cleaning, and servicing should typically be done monthly, while more comprehensive inspections can be scheduled semi-annually, depending on operational intensity.Q: Where can the machine be installed for optimal performance?

A: For best results, the machine should be installed in a spacious, well-ventilated industrial setting with access to a stable 440 V power supply. Adequate space allows for safe loading, unloading, and maintenance tasks.Q: What is the process to produce bottles using this machine?

A: Operators load the preforms into the machine, which then heats, positions, and blows them into the cavity molds to shape the bottles. Finished PET bottles are collected for further packing or distribution.Q: How do I benefit from choosing this PET blowing machine?

A: Users benefit from a reliable, high-capacity production unit that minimizes downtime and maximizes throughput. The machines warranty, energy-efficient electric supply, and easy operation contribute to lower running costs and increased productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bottle Making Machine Category

1 Ltr Semi Automatic Pet Oil Bottle Making Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage & Applications : Commercial

Operating Type : Semi Automatic

Power Source : Electricity

Semi Automatic Plastic Pet Bottle Making Machine

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage & Applications : Commercial

Operating Type : Automatic

Power Source : Electricity

Fully Automatic Water Bottle Making Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Usage & Applications : Commercial

Operating Type : Semi Automatic

Power Source : Electricity

Pet Fridge Bottle Making Machine

Price 365000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Usage & Applications : Commercial

Operating Type : Semi Automatic

Power Source : Electricity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free